NEWS

-

Marble Protective Film: The Ultimate Solution to Protect Your Investment

Yeslafilm.com - Marble Protective Film, Protective Film for Metal, Glass Protective Film Marble is a popular choice for flooring, countertops, and other surfaces due to its natural beauty and durability. However, it is also a costly investment that needs protection against damage from everyday wear and tear. Marble Protective Film is…Read more -

The Advantages Of Installing Window Protective Film On Your Car

Yeslafilm.com - Window protective film, Stone Protection Film, Release Liner Your car is a valuable investment, and you want to keep it looking and functioning its best for as long as possible. One way to achieve this is by installing Window protective film, a clear, thin layer of film applied…Read more -

Yeslafilm Offer Wide Range Of Protective Films

Aluminum Protective Film, paint protection film, Window Protective Film Yeslafilm is a leading company which offer different kinds of protective films. We offer premium range of films at the best market price. Aluminum Protective Film is water-based adhesive films developed for surface protective of stainless steel and other metal plates.…Read more -

Know About The Benefits of Self-Adhesive Film

Glass Protective Film, Self Adhesive Film, Flame Retardant Film Self-adhesive or static cling are the most common methods of installation. Some of them take a little more time and skills to install, but it is worth it. Sometimes it will be better to contact a handyperson or contractor to set…Read more -

Know About The Different Kinds of Protective Film

Protective Film, Carpets Protection Film, Polyethylene Film The protective film is a plastic material that covers or protects many surfaces. It is commonly used to protect the easily damaged surface from abrasion, marring, or scratching. Plus, it is used in various situations, such as during storage, transportation, assembly, or fabrication.…Read more -

Yeslafilm.com Produce High-Quality Protective Film

Aluminum Protective Film, Paint Protection Film Cost, Window Protective Film Yeslafilm.com is a leading supplier of window protection films that add safety, security, solar blocking, and insulation to your windows and other glass. Aluminum Protective Film is high strength with an easy release adhesive formulation film. The film uses high…Read more -

Yeslafilm.com Produce Top Quality Protection Film

Carpets Protection Film , Protective film, Polyethylene Film Yeslafilm.com is a renowned producer of different protection films and covers to protect a specific surface. Carpets Protection Film, gives protection and covering for an extended period. The film is perfect for reducing your snagging list at the end of a building,…Read more -

Yeslafilm.com Offer a Premium Range of Adhesive Film

Self Adhesive Film , Adhesive Film, Release Liner Yeslafilm.com is a leading provider of different kinds of Film and liners. Self Adhesive Film is equipped with pressure-sensitive self-adhesives. The materials are designed for vehicle and building graphics and are regularly converted for digital, cut and screen applications, such as banners…Read more -

Benefits of Using Aluminum Protective Film

Benefits of Using Aluminum Protective Film An Aluminum Protective Film is basically a layer of plastic film that is attached to an aluminum profile. The main purpose served by this film is protecting the produced aluminum profiles from all kinds of damages during inventory, transportation, installation and processing. Not to…Read more -

The Benefits of Using a Carpets Protection Film

carpets protection film, protective film, polyethylene film A carpets protection film is a highly useful and important product. It is a protective film that offers temporary protection for all kinds of carpets. These films are used for floor protection against all kinds of damages, like flooding, abrasion, spraying, painting, stages…Read more -

The Main Uses of Self-Adhesive Film

Self-adhesive film, adhesive film, release liner Self-adhesive film is a durable and strong material that can easily be applied to different surfaces for maximum protection. The film offers protection from different things like abrasions, scratches, shattering, vandalism, fading, UV damage, viruses and normal wear and tear. This is an affordable…Read more -

How is PE film made

We all use products that are not made in the same way. This includes polyethylene and polyester film. Most of us don’t even care about this kind of information. It needs to be available and manufactured! If you're not part of the majority and would like to learn more, read this article!…Read more -

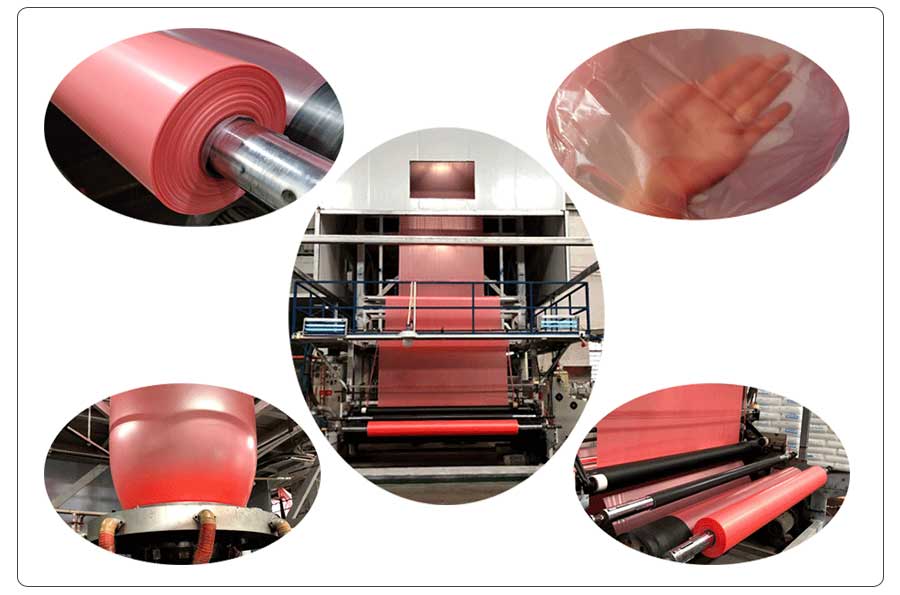

How is PE Film made?

It is common to use different types of products in daily life and not know how they are made. Polyethylene and polyester film are two examples. The truth is that most people don't even care much about such information. It's just necessary to make it available and be easily accessible. You don't…Read more -

How is PE film made?

We use many types of products every day and don't know how they were made. One example is polyethylene or polyester films. Most people don't care at all about this type of information. It only needs to be made and made available for us to use. If you don't want to be…Read more -

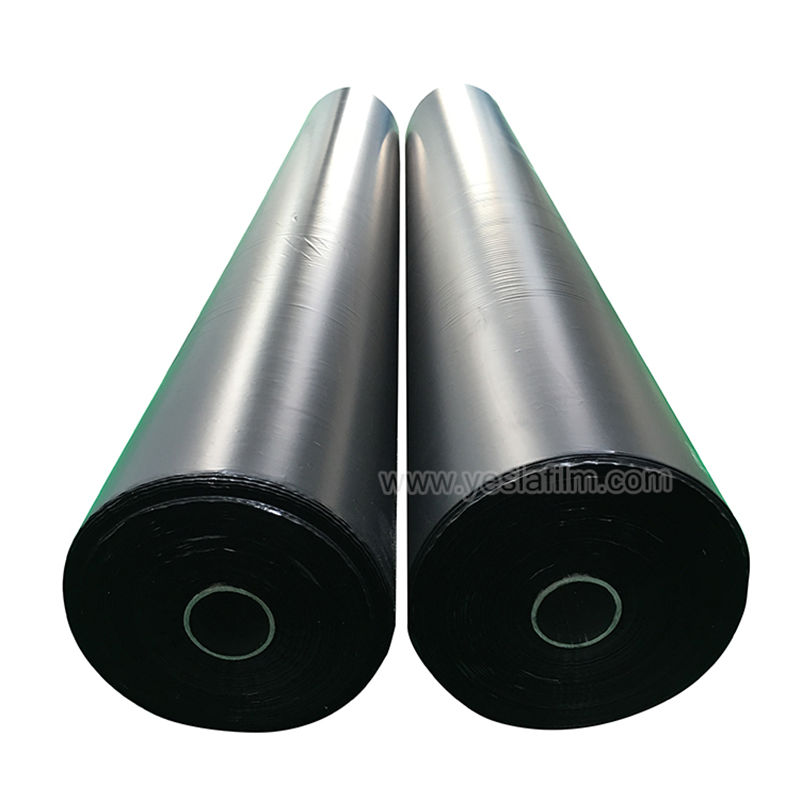

Types and types of stainless steel protective films

1. Protective Film made from white polyethylene (PE) A rubber adhesive layer and polyethylene (PE), is the most suitable protective film for most applications. This film is applied automatically to protect the surface if it is not specifically specified. The sheet plastic material has a nominal thickness of 80 micrometres. It is typically…Read more