Knowledge Popularization

-

Problems and analysis of dry composite of PE film

In dry compounding, there are often problems such as weak compounding, white spots after compounding, the astringency of the compound product, and poor heat sealing. There are many reasons for these problems. The following only discusses the problems arising from the dry compounding of the PE film. 1 Insufficient compound…Read more -

Theoretical analysis of the heat-sealing performance of PE film subjected to electronic shock

Polyethylene is a non-polar material, and its film has low surface tension. Generally, the surface tension of the film can be reached by corona treatment. Better printing results can be obtained above 38dyn/cm. This development is to select appropriate raw and auxiliary materials and reasonable process formulas, After the PE…Read more -

The difference between CPP and PE film

The coefficient of friction refers to the coefficient of sliding on the surface of the film, which has been learned in physics. The common point of CPP film and PE film is that they can be heat-sealed But there are many differences between the two. The mechanical strength and tensile…Read more -

Common faults and solutions of low-density polyethylene (LDPE) blown film

Common faults and solutions of low-density polyethylene (LDPE) blown film The film is just too sticky and therefore the gap is the poor cause of the issue: ① The rosin material model is wrong, it's not blown film grade low-density polythene resin particles, that doesn't contain open The content of…Read more -

How to choose polyethylene blown film material?

How to choose polyethylene-blown film material? The selected raw materials should be made of blown film grade polyethylene resin particles, containing an appropriate amount of slip agent to ensure thinness The opening of the membrane. The melt index (MI) of the resin particles should not be too large. If the…Read more -

Factors influencing the uniformity of protective film coating

The basic factors of the uniformity of the protective film coating are several conditions directly related to the coating process: coated substrate, adhesive, coated steel roller/rubber roller, laminating machine, etc. There are many factors influencing the uniformity of coating, including operators, machines, materials, methods, and rings, but the basic factors…Read more -

What are the common PET protective films

The protective film is one of the most peer-to-peer protective stickers on the single-level opportunity. The three-layer PET protective film is loaded for the mask and the product. The boutique adopts a polyester case. The mask is hard on the line, more scratch-resistant, and anti-static during permanent disasters, it also…Read more -

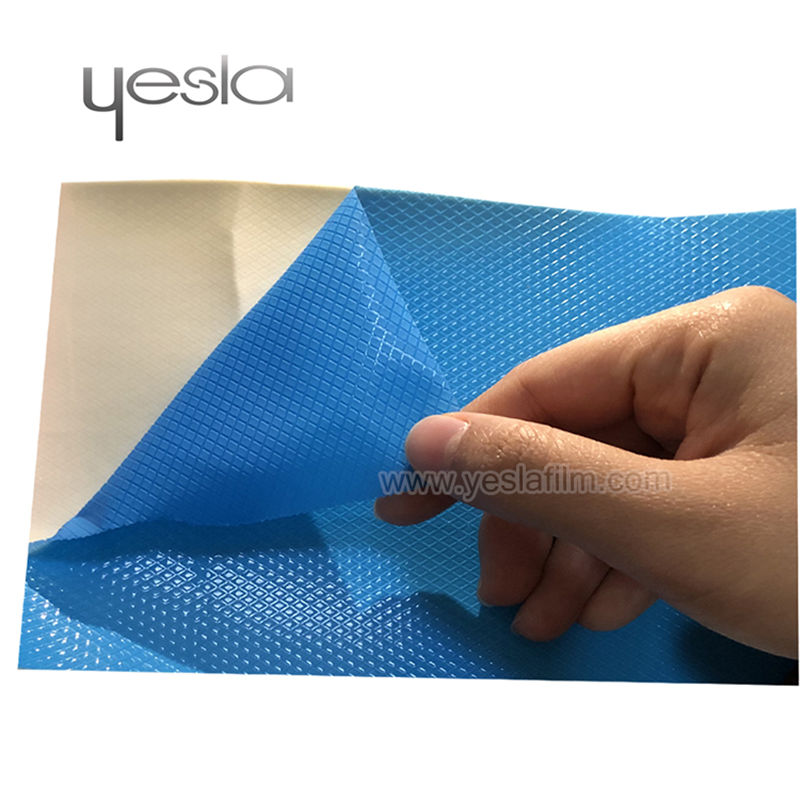

Protective film characteristics and technical requirements

According to the viscosity points: Ultra-low-viscosity protective film, low-viscosity protective film, medium-low-viscosity protective film, medium-viscosity protective film, high-viscosity protective film, ultra-high-viscosity protective film 1. Ultra-low-viscosity protective film (ie, micro bottom Adhesive) Features: thick (≥0.03m±0.003), width (≤1.3), high (100-1500), base material (PE), peel strength (≤5g/cm), temperature resistance (60), stretch Rate…Read more