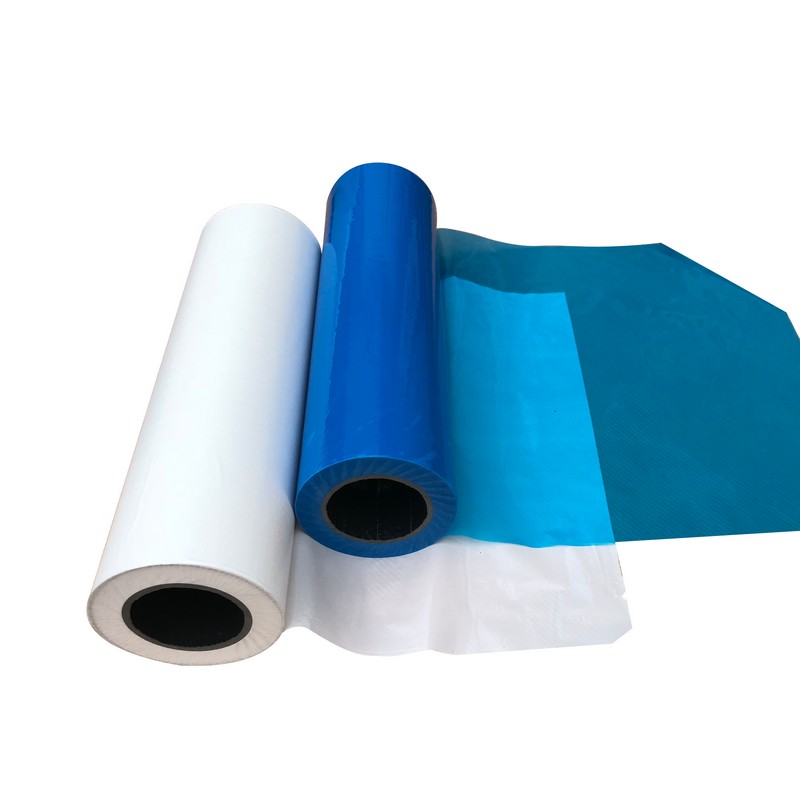

Protective film

-

Different types of stainless steel protective film

1. Protective Film made of white polyethylene (PE). For most applications, polyethylene (PE) with a rubber adhesive is the best protective film. When the quality of the film is not specified, this film is used by default to protect the surface. The sheet of plastic material is nominally 80 micrometres thick. It may…Faitau atili -

Factors influencing the uniformity of protective film coating

The basic factors of the uniformity of the protective film coating are several conditions directly related to the coating process: coated substrate, adhesive, coated steel roller/rubber roller, laminating machine, ma isi. There are many factors influencing the uniformity of coating, including operators, machines, materials, methods, and rings, but the basic factors…Faitau atili -

Protective film characteristics and technical requirements

According to the viscosity points: Ultra-low-viscosity protective film, low-viscosity protective film, medium-low-viscosity protective film, medium-viscosity protective film, high-viscosity protective film, ultra-high-viscosity protective film 1. Ultra-low-viscosity protective film (ie, micro bottom Adhesive) Vaega: thick (≥0.03m±0.003), width (≤1.3), high (100-1500), base material (PE), peel strength (≤5g/cm), temperature resistance (60), stretch Rate…Faitau atili