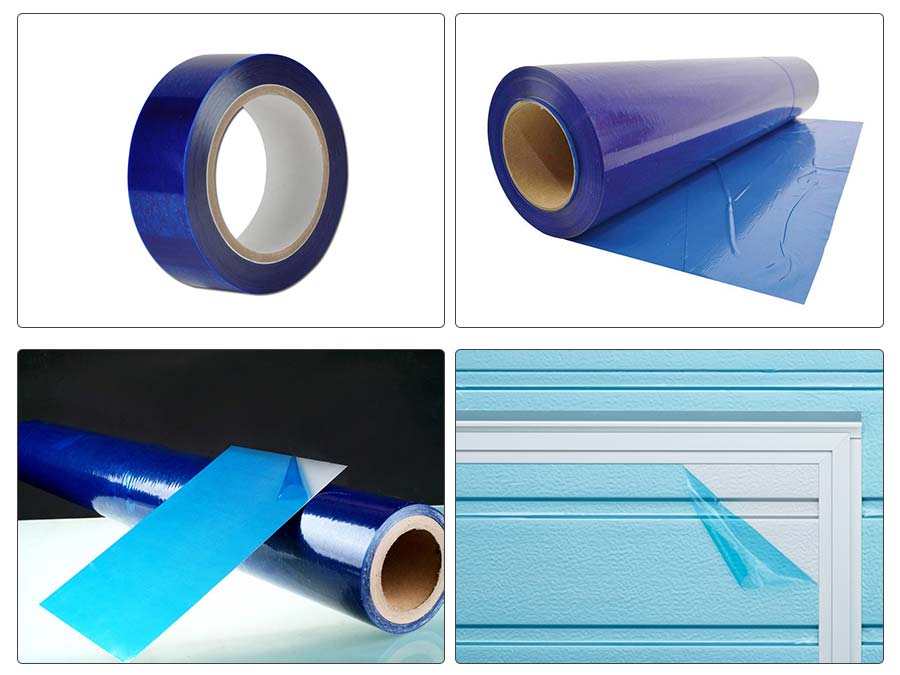

1. Ultra-low-viscosity protective film (Slightly sticky)

Uses: Easy to use, easy to stick and tear, no glue residue, suitable for organic plates, instruments, aluminum-plastic panels, display screens, glass lenses, plastic lenses, etj.

2. Low viscosity protective film

Usage: Stable adhesion, good adhesion, good peeling performance, no glue residue, suitable for silk screen printing, steel mirror plate, smooth plastic plate, titanium metal, nameplate, etj.

3. Medium adhesive protective film

Usage: Stable adhesion, good adhesion, good peeling performance, no glue residue, suitable for surface protection of fine-grained frosted boards, and general hard-to-stick materials.

4. Medium and low viscosity protective film

Usage: Stable adhesion, good adhesion, good peeling performance, no glue residue, suitable for stainless steel plates, ceramic tiles, furniture Polaroid plates, marble, artificial stone, etj.

5. High viscosity protective film

Usage: Stable adhesion, good adhesion, good peeling performance, no glue residue, suitable for fine-grained matte boards, hard-to-stick plastic boards, aluminum-plastic panels, etj.

6. Ultra-high viscosity protective film

Usage: Very high viscosity, water-based acrylic is used as pressure-sensitive adhesive, easy to use, easy to stick and tear, no glue residue. Suitable for hard-to-stick materials such as rough-grained aluminum plates.

Order our PE High-Density Film in bulk, affordable price is available. Contact Yeslafilm Polyethylene film manufacturer